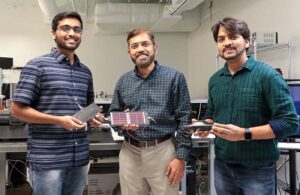

UCF and NASA researchers have recently developed a power suit for an electric car that is as strong as steel, lighter than aluminum and helps boosts the vehicle’s power capacity.

The suit is made of layered carbon composite material that works as an energy-storing supercapacitor-battery hybrid device due to its unique design at the nanoscale level.

“Our idea is to use the body shells to store energy to supplement the power stored in batteries,” says study co-author Jayan Thomas, the team leader and a professor in UCF’s NanoScience Technology Center and Department of Materials Science and Engineering.

“The advantage is that this composite can reduce the weight of your car and increase the miles per charge,” he says. “It is as strong as or even stronger than steel but much lighter.”

“This application, as well as many others, could be on the horizon one day as the technology advances in its readiness level,” says Luke Roberson, study co-author and a senior principal investigator for research and development at NASA’s Kennedy Space Center.

These materials could be employed as frames for cube satellites, structures on off-world habitats, or even as part of futuristic eyewear, such as mixed and virtual reality headsets.

“There are lots of potential infusion points within the economy as well as for future space exploration,” Roberson says. “This is, in my mind, a huge advancement of the technology readiness level to get us to where we need to be for NASA mission infusion.”

On cars, the supercapacitor composite material would get its power through charging, like a battery, as well as when the car brakes, Thomas says.

“Its charge-discharge cycle life is 10 times longer than an electric car battery,” he says.

The materials used are also nontoxic and nonflammable, which is very important for passenger safety in case of an accident, he says.

“This is a huge improvement over past approaches that have suffered from issues with toxic material, flammable organic electrolytes, low life cycles or poor performance,” Thomas says.

Study co-author Kowsik Sambath Kumar, a doctoral student in Thomas’ lab, developed a way to vertically align nanoscale graphene on carbon fiber electrodes.

Kumar says one of the most important developments from this supercapacitor composite is that it is lightweight.

“Now in electric cars, the battery is 30% to 40% of the weight,” he says. “With this energy storing composite we can get additional mileage without increasing the battery weight, further it reduces the vehicle weight while maintaining high tensile, bending and impact strength. Whenever you decrease that weight, you can increase the range, so this has huge applications in electric cars and aviation.”

Pandey agrees and highlights its usefulness for the space sector.

“Making a cubic satellite out of this composite will make the satellite light in weight and will help to eliminate the heavy battery pack,” he says. “This could save thousands of dollars per launch. Further, free volume gained by the removal of big batteries could help pack in more sensors and testing equipment, increasing the functionality of satellite,” Pandey says. “Supercapacitor-battery hybrid behavior is ideal for cubesats since it can charge in minutes when a satellite orbits over the solar-lit side of the Earth.

Roberson says the technology is currently at a technology readiness level of five, which means it has been tested in a relevant environment before moving to being tested in a real environment, such as on a space flight, which would be level six testing.