The electric vehicle (EV) industry is rapidly expanding in 2025, so the environmental implications of EV production are under increased scrutiny. While EVs help reduce tailpipe emissions, their manufacturing especially batteries and structural components still results in significant carbon emissions. This is where the use of low-carbon materials is important.

By using low carbon materials, car manufacturers are decreasing the emissions throughout their supply chain – from mining, to production and recycling of EVs. Plus, it greatly reduces the carbon emissions from the manufacturing of electric vehicles, while also improving electric vehicles sustainability and efficiency. Let’s examine the top 10 low-carbon materials that will change EV manufacturing in 2025.

1. Bio-Based Plastics

Bio-based plastics are made from renewable biological sources such as corn starch, sugarcane, algae, and other plant-based raw materials. Unlike traditional plastics derived from petroleum, these low-carbon materials help cut down fossil fuel usage and lower carbon emissions.

Car manufacturers that produce electric vehicles are progressively integrating bio-based plastics into dashboards, interior finishes, seat materials, and even under-the-hood parts. Most notably, Ford and Toyota have pioneered using foams and bioplastics derived from soy in several parts of their vehicles. This is beneficial because these foams and bioplastics are compostable and biodegradable and decrease our reliance on crude oil.

The automotive industry is moving toward bio-based plastics so that the industry can utilize low-carbon materials that produce less greenhouse gas emissions compared to petroleum-based plastics, while still providing similar performance as the previous materials.

2. Recycled Steel

Steel remains an essential material in constructing vehicle frames, bodies, and structural car parts. However, making virgin steel involves a considerable amount of energy consumption and very large CO₂ emissions. By using recycled steel, a critical form of low-carbon materials, the carbon footprint in EV production is significantly reduced.

The World Steel Association reports that recycled steel can reduce emissions by up to 58% compared to new steel. Car companies like Volvo and Mercedes-Benz are putting recycled materials into electric vehicles as part of their move to incorporate circular economy principles. Utilizing low-carbon materials like recycled steel allows for resource conservation because it minimizes the extraction and processing of raw materials.

3. Lithium Iron Phosphate (LFP) Batteries

Lithium Iron Phoshate or LFP batteries are gaining in popularity in 2025 due to their decreased environmental impact. Unlike Nickel-Manganese-Cobalt (NMC) batteries, lithium-iron-phosphate (LFP) batteries incorporate the lower-carbon materials iron and phosphate, which are more abundant and much less damaging to the environment.

The use of these low-carbon materials produce batteries with longer life cycles, better thermal stability, and less reliance on rare metals. Tesla, BYD, Tata Motors, and others have incorporated LFP batteries in multiple models. The elimination of cobalt (often connected to unethical mining practices) is not only essential for bettering the sustainability reputation of vehicles but improving their overall sustainability.

Using LFP batteries gives automotive companies the ability to produce a lower carbon, safer, and cheaper battery for vehicles, while also supporting further sustainability in the manufacturing process.

4. Sodium-Ion Batteries

Despite being relatively nascent, sodium-ion batteries provide a potential alternative for EV battery chemistry. Sodium is one of the most abundant elements on Earth, providing a renewable resource over Lithium. These low-carbon materials could ease the strain on global lithium supply chains and our reliance on other limited critical minerals.

In 2025, companies such as CATL and Faradion are already incorporating sodium-ion battery technology into commercial EV transportation. While these batteries are in their infancy, they are expected to provide a cost-effective, low-emission energy storage solution, ultimately increasing our available portfolio of renewable and low-carbon materials in manufacturing applications for EVs.

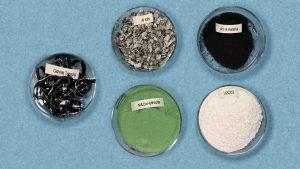

5. Recycled Battery Materials

Battery recycling is one of the most effective mechanisms to mitigate sustainability impact associated with electric vehicle production. By recovering important metals like lithium, cobalt and nickel from closed battery systems, manufacturers reduce the need for new mining – which is a carbon-intensive process.

These recycled inputs are termed low-carbon inputs, thereby reducing the carbon emissions associated with mining and processing raw materials. Companies like Redwood Materials, Attero and Glencore are leading the way in battery recycling while also providing sustainable materials back into the EV value chain.

Using low-carbon materials from recycled batteries also follows a circular economy approach by turning waste into new resources.

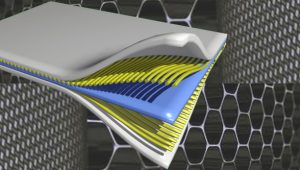

6. Lightweight Composites

A proven method of improving energy efficiency is to reduce the weight of the vehicle. Low-carbon lightweight composites, such as carbon fiber-reinforced plastics (CFRP), fiberglass, and natural fiber composites, have firmly established themselves as critical low-carbon materials in the planning and design of new EVs.

These lightweight products lower the energy demands for driving a vehicle, resulting in reduced energy consumption and emissions over the vehicle’s lifecycle for the manufacturing, operation, and end-of-life assessments. BMW and Audi are already using carbon fiber and hemp-based composites for their electric vehicle platforms.

Lightweight low-carbon materials, in addition to energy efficiency, can improve safety and durability, potentially allowing OEMs to meet targets for EV performance, price and reduced environmental footprint, in a business-as-usual way, possibly in 2025.

7. Aluminum

Aluminum has traditionally been recognized for its breadth of strength-to-weight ratio. By 2025, aluminum has taken an additional role as a low-carbon material, primarily due to its elevating levels of recycling capacity. Aluminum that is recycled uses approximately 5% of the energy (and, therefore, carbon savings) associated with producing virgin aluminum.

Companies like Novelis and Hindalco are focusing on ultra-low-carbon aluminum from renewable smelting sources and using closed-loop recycling systems to produce aluminum. Automakers like Tesla and Jaguar Land Rover have utilized aluminum for their metal bodies and chassis extensively in their electric vehicle line-up.

The use of aluminum as one of the primary low-carbon substitutes, is viewed as a “clear advantage” to reduce weight and improve energy efficiency on their electric vehicles.

8. Green Hydrogen

Green hydrogen, produced using renewable energy sources like wind or solar, is not a physical material used in car bodies but is still classified among low-carbon materials due to its application in fuel cell electric vehicles (FCEVs).

Green hydrogen emits only water vapor when used, making it an ideal zero-emission fuel. Automakers such as Hyundai, Toyota, and Honda continue to develop hydrogen-powered EVs with a focus on commercial fleets and long-distance mobility.

The infrastructure for green hydrogen production is also improving, supported by advanced low-carbon materials such as efficient membranes and catalysts in electrolyzers.

9. Advanced Electrolyzers and Membranes

Producing green hydrogen efficiently requires high-performance electrolyzers and membranes made from low-carbon materials like ion-exchange membranes, noble-metal-free catalysts, and bio-based polymer composites.

These technologies ensure that the hydrogen produced is truly clean and viable for long-term EV applications. Innovations from companies like Plug Power, Nel Hydrogen, and Bloom Energy are focused on making these systems cost-effective and scalable in 2025.

As the hydrogen economy evolves, these enabling technologies represent critical low-carbon materials that will power next-generation EVs and hydrogen refueling infrastructure.

10. Optimized Battery Size and Design

A commonly not considered, yet highly successful strategy for reducing emissions is with appropriately sized battery packs. Many battery packs on the road today are too large. Those larger battery packs weigh more. Even if that energy in the battery pack is never used in real-world driving, it adds excess weight and manufacturing emissions. Designing batteries that provide equivalent energy usage as the actual driving profile is one effective way to reduce the demand for raw materials.

The transition to purpose-built optimization for batteries is driven by smart engineering and data analysis which, requires reduced low-carbon materials for every unit manufactured. Brands such as Lucid Motors and Rivian reflect this trend, with battery packs that prioritize efficiency beyond utility.

EV manufacturers are moving towards better performance while using low-carbon materials in smarter ways.

Conclusion: The Future of Low-Carbon EV Manufacturing

In 2025, as the world grapples with the environmental cost of mobility, low-carbon materials will become a necessity instead of just an option. From batteries and body panels, to interiors and fuel cells, sustainable advances can be made throughout all levels of EV manufacturing.

The transition to low-carbon materials is not only reducing emissions but also allowing for cost savings, security of materials, and ethical sourcing. National governments, automakers, and suppliers of all sizes are committed to this green transition and modernizing transportation through their investments, incentives, research and development, and regulations.

As India and the rest of the world embrace cleaner means of transport, the transition to low-carbon materials will also define the next generation of electric vehicles. Every piece of each vehicle, whether it be recycled aluminum, bio-plastics, or innovative batteries, is part of a lower-emission future.

For EV manufacturers and suppliers in 2025, investing in low-carbon materials is both an environmental responsibility and a strategic advantage.