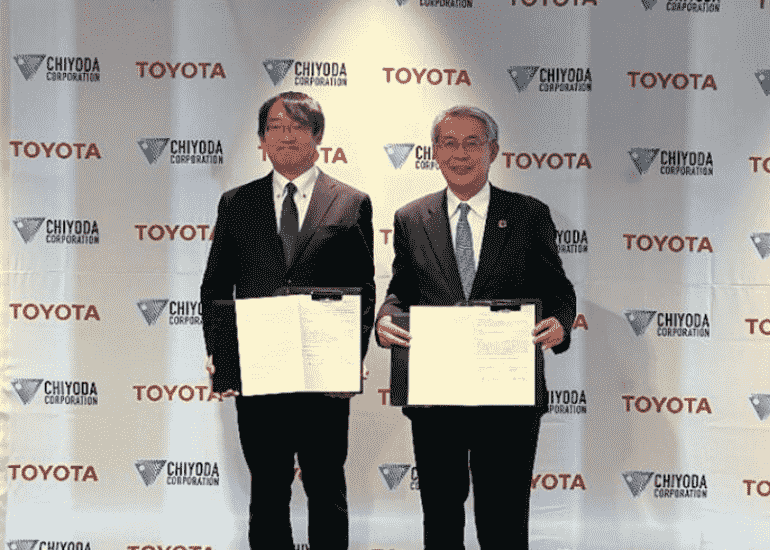

Chiyoda Corporation and Toyota Motor Corporation have agreed to jointly develop a large-scale electrolysis system and construct a strategic partnership and have signed a basic agreement on cooperation.

The purpose is to help the Japanese government meet its targets for the adoption of electrolysis equipment in Japan and abroad as part of its Basic Strategy on Hydrogen.

Toyota’s fuel cell technology, along with Chiyoda’s processing plant design and large-scale plant construction technologies, will be combined to create a competitive large-scale electrolysis system. This will enable for adaption to the rapidly developing hydrogen production markets both inside and beyond Japan.

The objective is to create an electrolysis system that produces hydrogen efficiently while being the world’s smallest in size.

To respond to the various needs of customers, such as the amount of hydrogen used or plant floor area limitations, 5 MW-class equipment will be used as the basic unit for development (floor area: 2.5 m x 6 m, hydrogen production capacity: approximately 100 kg/hr) and will be combined to create a standard package, allowing the construction of large-scale electrolysis systems.

The benefits of this equipment include the fact that it takes up roughly half the floor space of traditional equipment, is easy to maintain, allows for simpler transportation, shorter on-site building periods, and cheaper civil engineering and construction expenses. Toyota’s expertise in industrial products and Chiyoda’s expertise in plant engineering will be combined and optimised, resulting in cost savings, increased production efficiency, and more stable quality for the electrolysis systems required to produce green hydrogen.

With the signing of this fundamental collaboration agreement, the deployment of an electrolysis system in Hydrogen Park at the Toyota Honsha Plant will begin in FY2025. It will eventually be increased to 10 MW and utilised for verification and development. Any further developments will be shared when they occur.