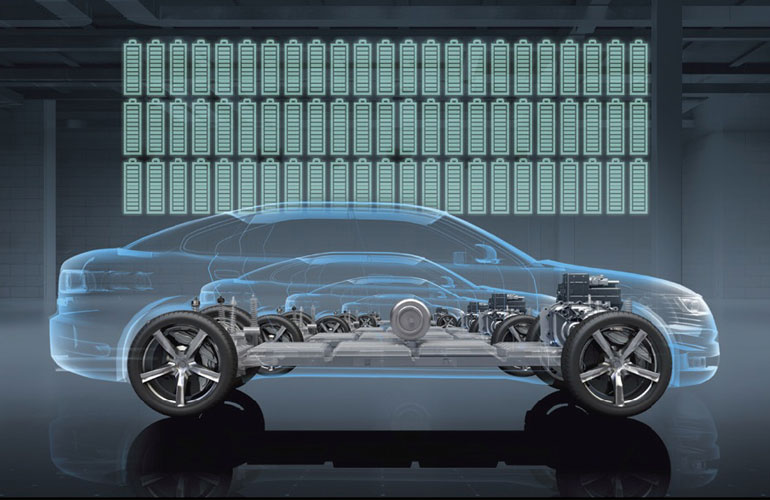

Electric vehicles (EVs) are heralded as the future of sustainable transportation, primarily due to their potential to reduce greenhouse gas (GHG) emissions compared to internal combustion engine (ICE) vehicles. At the heart of every EV lies the traction battery pack, which stores and supplies energy for propulsion. However, the environmental impact of EVs is not limited to their operation; a comprehensive lifecycle assessment (LCA) of the traction battery packs is essential to understand their true sustainability footprint. This article examines the lifecycle environmental impact of traction battery packs, from raw material extraction to manufacturing, usage, and recycling, and highlights the role of EV charging infrastructure in mitigating their overall environmental impact.

What is Lifecycle Assessment (LCA)?

Lifecycle assessment (LCA) is a methodology used to evaluate the environmental impacts associated with all stages of a product’s lifecycle. For traction battery packs in electric vehicles, this includes:

- Material extraction and processing

- Battery manufacturing

- Operational phase (EV use and EV charging)

- End-of-life treatment (reuse, recycling, or disposal)

The LCA approach ensures that the environmental benefits of electric vehicles are not assessed solely based on their zero tailpipe emissions, but also on the emissions and resource use throughout the battery’s lifecycle.

-

Material Extraction and Processing

The production of traction battery packs begins with the extraction of raw materials such as lithium, cobalt, nickel, and manganese. These materials are critical components of lithium-ion batteries, the most widely used battery technology in electric vehicles. However, mining and processing these materials come with significant environmental impacts:

- Resource Depletion: Mining lithium and cobalt depletes natural resources and disrupts ecosystems. Cobalt mining, for instance, is often concentrated in regions with lax environmental regulations.

- Energy-Intensive Processing: The refining and processing of raw materials consume substantial energy, contributing to GHG emissions, especially when fossil fuels power the operations.

- Water Usage: Lithium extraction through brine evaporation requires large quantities of water, leading to water scarcity in arid regions like South America’s “Lithium Triangle.”

To mitigate these impacts, EV manufacturers are exploring alternative battery chemistries, such as solid-state batteries or lithium iron phosphate (LFP) batteries, which use fewer rare materials. Additionally, responsible sourcing and urban mining, which involves recycling metals from used batteries, can significantly reduce the environmental burden.

-

Battery Manufacturing

The manufacturing phase of traction battery packs is energy-intensive, with most of the emissions arising from the electricity used in battery cell production. For example, the production of a single battery pack for an electric vehicle can emit 2-6 tons of CO₂, depending on the energy mix used in manufacturing.

- Energy Mix Influence: Regions with cleaner energy grids (such as those relying on renewable sources) result in lower emissions during battery production. In contrast, production facilities in coal-dependent regions emit more carbon.

- Improving Manufacturing Efficiency: EV manufacturers are adopting cleaner energy sources for battery factories, such as solar or wind power, to reduce emissions.

While the emissions from manufacturing are significant, they are offset over time by the lower operational emissions of electric vehicles when compared to ICE vehicles.

-

Operational Phase: EV Usage and EV Charging

The operational phase of traction battery packs is where electric vehicles achieve their environmental advantage over ICE vehicles. EVs produce zero tailpipe emissions, making them cleaner for urban areas and reducing air pollution. However, the environmental impact during this phase depends heavily on EV charging infrastructure and the energy sources powering it:

- Clean Energy for EV Charging: If electric vehicles are charged using electricity generated from renewable sources (solar, wind, or hydro), their lifecycle emissions are significantly reduced. Conversely, EV charging from coal- or gas-based grids diminishes their environmental benefits.

- Smart Charging and Grid Optimization: Integrating smart EV charging solutions can optimize the load on power grids, ensuring that EV charging occurs during periods of high renewable energy generation. This minimizes reliance on fossil fuel-based power plants.

- Battery Efficiency: Advances in battery technology, such as increased energy density and better thermal management systems, enhance the efficiency and longevity of traction battery packs, reducing their overall lifecycle impact.

It is also worth noting that driving an electric vehicle for longer distances allows the emissions associated with battery production to be spread over a greater mileage, further improving the environmental performance of EVs.

-

End-of-Life Treatment: Recycling and Reuse

The end-of-life phase of traction battery packs is crucial to minimizing their environmental footprint. If not properly managed, used EV batteries can contribute to hazardous waste and resource loss. Fortunately, innovations in battery recycling and second-life applications are creating sustainable pathways for end-of-life management:

- Battery Recycling: Advanced recycling processes, such as hydrometallurgical and pyrometallurgical methods, enable the recovery of valuable metals (lithium, nickel, cobalt) from used batteries. Urban mining techniques are increasingly being applied to reduce the need for new raw materials.

- Second-Life Applications: Traction battery packs that no longer meet EV performance standards can be repurposed for less demanding applications, such as energy storage systems for renewable energy grids. This extends the battery lifecycle and reduces the demand for new batteries.

With improvements in recycling infrastructure and closed-loop supply chains, the environmental impact of EV batteries can be significantly reduced, aligning with the principles of the circular economy.

Comparing EVs to ICE Vehicles

When assessing the full lifecycle environmental impact of EVs and their traction battery packs, electric vehicles still outperform ICE vehicles in terms of overall emissions. Key comparisons include:

- Operational Emissions: EVs have zero tailpipe emissions, while ICE vehicles continue to emit CO₂, nitrogen oxides, and particulate matter during operation.

- Energy Source: The emissions of EVs depend on EV charging infrastructure. As grids become cleaner, EVs will continue to decarbonize, whereas ICE vehicles cannot escape their fossil fuel reliance.

- Lifecycle Savings: Studies show that even when accounting for battery production, electric vehicles produce up to 50% fewer emissions than ICE vehicles over their lifetime.

The Role of EV Charging Infrastructure

An efficient and clean EV charging infrastructure is essential to maximizing the environmental benefits of EVs. Integrating renewable energy sources into charging networks ensures that electric vehicles truly reduce carbon emissions. Key initiatives include:

- Solar-Powered Charging Stations: Installing solar panels at EV charging stations can reduce dependence on grid electricity.

- Smart Charging: EVs equipped with smart charging capabilities can align their charging schedules with periods of high renewable energy availability.

- Vehicle-to-Grid (V2G): V2G technology enables EVs to supply excess energy back to the grid, supporting renewable energy integration and grid stability.

Conclusion

Assessing the lifecycle environmental impact of traction battery packs highlights the complexities of EV sustainability. While raw material extraction and battery production present challenges, innovations in recycling, cleaner manufacturing, and smart EV charging infrastructure are driving improvements. Electric vehicles, supported by renewable-powered EV charging networks, remain a critical solution for reducing transportation-related emissions and achieving global climate goals. By addressing these challenges, EVs can deliver a cleaner, greener future for mobility.