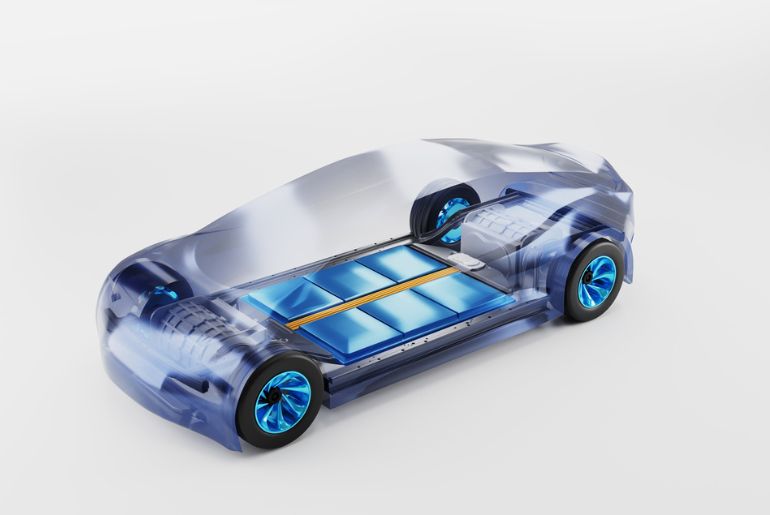

Electric vehicles (EVs) represent the future of sustainable transportation, offering a cleaner alternative to internal combustion engine vehicles. Central to their operation are lithium-ion batteries, which store and supply the energy needed to power the vehicle. However, the performance, safety, and longevity of these batteries are heavily dependent on effective thermal management. Battery thermal management systems (BTMS) are thus critical components in EV powertrains, ensuring that batteries operate within optimal temperature ranges, preventing overheating, and enhancing overall efficiency.

Understanding Battery Thermal Management Systems in EV Batteries

Fundamental Principles of BTMS

- Heat Generation in Batteries: Batteries generate heat during charging and discharging cycles due to internal resistance. Managing this heat is crucial to maintain battery efficiency and safety.

- Temperature Impact on Battery Performance: Extreme temperatures can degrade battery performance, reduce capacity, and shorten lifespan. Proper thermal management ensures batteries remain within optimal temperature ranges.

Components of BTMS

- Cooling Systems: These include liquid and air cooling systems designed to dissipate heat away from the battery pack.

- Heating Systems: Necessary for maintaining battery performance in cold climates by preventing the battery from dropping to temperatures that can impede its function.

- Thermal Interface Materials (TIMs): Materials that enhance thermal conductivity between battery cells and cooling systems, ensuring efficient heat transfer.

Advanced Cooling Technologies in Batteries for BTMS

Liquid Cooling Systems

- Direct Liquid Cooling: Involves circulating coolant directly around the battery cells. This method provides highly efficient thermal management and is used in high-performance EVs.

- Indirect Liquid Cooling: Coolant circulates through channels within a cooling plate in contact with the battery cells, offering a balance between efficiency and complexity.

Air Cooling Systems

- Forced Air Cooling: Utilizes fans to direct airflow over battery packs, suitable for less demanding applications but less efficient compared to liquid cooling.

- Natural Air Cooling: Relies on ambient air circulation, often used in less critical applications due to its lower efficiency.

Emerging Cooling Technologies

- Phase Change Materials (PCMs): Materials that absorb and release thermal energy during phase transitions, providing passive thermal management.

- Immersion Cooling: Involves submerging battery cells in dielectric fluids that absorb heat, offering high efficiency but with added complexity and cost.

Heating Solutions for Cold Climates

Resistive Heating

- Electrical Heaters: Integrated within the battery pack to provide heat during cold starts, ensuring batteries remain at operational temperatures.

- PTC Heaters: Positive Temperature Coefficient heaters that adjust resistance as temperature changes, providing self-regulating heating solutions.

Heat Pumps

- Reversible Heat Pumps: Capable of both heating and cooling, providing a versatile solution for maintaining optimal battery temperatures year-round.

Integration with Battery Management Systems in Thermal Batteries

Real-Time Monitoring

- Temperature Sensors: Placed throughout the battery pack to provide real-time data on thermal conditions, enabling precise control of BTMS.

- Data Analytics: Advanced algorithms analyze temperature data to predict and prevent thermal events, enhancing safety and performance.

Control Algorithms

- Thermal Management Algorithms: Sophisticated control algorithms optimize the operation of heating and cooling systems, balancing efficiency and battery health.

- Predictive Maintenance: AI-driven predictive maintenance can identify potential thermal issues before they become critical, reducing downtime and extending battery life.

Challenges and Innovations in Management System of Thermal EV Batteries

Material Challenges in Management of Batteries

- Thermal Conductivity: Developing materials with higher thermal conductivity for better heat dissipation.

- Durability: Ensuring materials can withstand the thermal cycling and mechanical stresses within the battery environment.

System Design

- Compactness: Designing BTMS that are compact yet effective, to fit within the limited space of EV powertrains.

- Energy Efficiency: Ensuring BTMS do not consume excessive energy, which would otherwise reduce the overall efficiency of the EV.

Innovations

- Nanotechnology: Using nanomaterials to enhance thermal properties and improve heat transfer efficiency.

- Smart Materials: Developing materials that can change properties in response to thermal conditions, providing adaptive thermal management solutions.

Future Prospects: Advancements in BTMS Technology in EV Batteries

Integration with Advanced Powertrains

- Hybrid BTMS: Combining liquid and air cooling systems to optimize thermal management across a range of operating conditions.

- Integration with Electric Drive Systems: Seamless integration of BTMS with electric drive systems for coordinated thermal management and improved efficiency.

Next-Generation Materials

- Graphene: Exploring the use of graphene for its exceptional thermal conductivity and strength.

- Aerogels: Investigating aerogels for their lightweight and high thermal insulation properties.

AI and Machine Learning

- Predictive Thermal Management: Utilizing AI to predict thermal loads and proactively adjust BTMS settings for optimal performance.

- Self-Learning Systems: Developing BTMS that can learn from operational data to continuously improve their efficiency and effectiveness.

The Path Forward for Thermal Management Systems in EV Batteries

Effective battery thermal management is crucial for the performance, safety, and longevity of electric vehicles. As EV adoption continues to grow, advancements in BTMS technology will play a pivotal role in ensuring these vehicles can meet the demands of drivers and the environment.

By integrating cutting-edge cooling and heating technologies, leveraging advanced materials, and employing AI-driven control systems, the future of BTMS promises to enhance the efficiency and reliability of EV powertrains, paving the way for a sustainable transportation future.