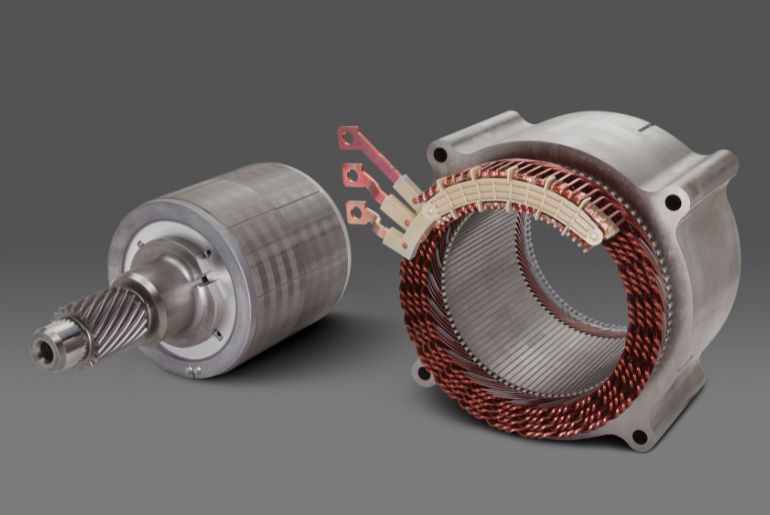

Due to consumer demand for locally made and ecologically friendly EVs, electric motors without rare earth elements are growing in popularity in 2025. Two crucial parts for traditional permanent magnet motors, neodymium and dysprosium, are imported in significant amounts from China. This reliance has led to concerns about price changes and political risks as global tensions and supply chain problems continue to plague automakers.

In order to address this, Indian institutions such as IIT Delhi are putting a lot of effort into developing hybrid reluctance motors and switched reluctance motors (SRM) that require fewer or no rare earth elements. These motors have a basic rotor design without magnets making them tough less hot, and cheaper to make. Also, SRMs last a long time and can handle tough weather—which is really important for India’s different climate areas.

New prototypes created as part of India’s Electric Mobility Mission Plan have shown they can compete when it comes to torque density and power efficiency. With the current designs that are available, it is highly likely that these processes can be extended to both the electric vehicles for passengers and the ones for two-wheelers. The Mahindra Electric and Bharat Heavy Electricals Limited.

To build on this, several prestigious companies including Mercedes-Benz, Renault, and BMW are exploring the possibility of introducing magnet-free motor designs. The companies have declared a global scope of the initiative, using magnet. When it comes to the design of EV drivetrains, this paradigm shift represents a significant turning point where performance, cost, and environmental priorities converge.

Lightweight Materials: Reinventing the EV Structure

Weight optimization remains one of the most influential factors in EV design. In addition to lowering manufacturing emissions, reducing vehicle mass directly improves handling dynamics, battery range, and acceleration. By 2025, lightweight materials like high-strength steel, carbon fiber composites, and aluminum alloys will have reached industrial maturity.

The aluminum-intensive chassis platforms used by BMW’s iX and Tesla’s Model Y reduce conventional frame weight by up to 30%. In addition to increasing energy efficiency, these reductions make it possible to use advanced structural engineering to improve crash safety. The Air Sapphire’s monocoque cabin design uses carbon-fiber-reinforced polymer (CFRP) by Lucid Motors to add stiffness and reduce drag, providing luxury without compromising sustainability.

Even Indian startups like Pravaig Dynamics and Ola Electric are exploring fiber-reinforced polymer panels for scooters and EV taxis. Their goal: balance cost-efficiency, recyclability, and passenger safety. Tata Elxsi and JBM Auto have partnered with global composites manufacturers to localize advanced material production, indicating the growing maturity of India’s EV materials supply chain.

In order to incorporate lightweight components without sacrificing strength, manufacturers are also utilizing multi-material joining technologies such as friction stir welding, ultrasonic metal welding, and structural adhesives. These joining methods improve design flexibility, especially when combining suspension systems, crash structures, and battery enclosures in confined spaces.

Ultra-Fast Charging Systems: From 30 Minutes to 10

Ultra-fast charging is not a concept of the future. Leading battery innovators like CATL and BYD are revolutionizing EV charging in 2025. Unveiled in 2023 and currently offered in a number of 2025 EV models, CATL’s Shenxing Superfast Charging LFP battery provides 400 km of range with a 10-minute charge under ideal circumstances. Low-resistance electrolyte design, intelligent thermal management integration, and nano-crystal coating enabled this performance improvement.

Exide and Tata Motors have started testing high-voltage platforms in India that can accommodate 800V charging architecture. For commercial EV fleets, these systems significantly cut down on battery replenishment times, especially for e-bus and last-mile delivery applications. Ola Electric’s upcoming four-wheeler is also rumored to integrate 350kW charging support, reflecting this broader move toward ultra-rapid energy transfer.

EVs like the XPeng G9 and BYD Yangwang U8 are already offering 10–15 minute partial top-ups using 800V and 1000V high-voltage platforms.By installing next-generation chargers with a maximum output of 480 kW, infrastructure companies like ABB, Siemens, and Tata Power are cutting down on wait times at public stations and facilitating real long-distance EV travel.

Urban fast-charging corridors, especially those on NH44, NH48, and NH16, are being given priority by India’s Ministry of Power in accordance with its updated FAME III guidelines. This infrastructure upgrade is critical to supporting the next generation of electric logistics and intercity mobility.

Smart Thermal Management: The Silent Enabler of EV Longevity

Smart thermal management systems (TMS) are a crucial but frequently overlooked EV component in 2025. The need for effective heat regulation in batteries, inverters, and cabins has increased dramatically as EVs get more powerful and can charge ultra-fast.

To guarantee even temperature distribution, businesses like Mahle, Valeo, and Modine are combining phase-change materials, heat pumps, and liquid cooling loops. The “Octovalve” from Tesla and the “Integrated Thermal Module” from Hyundai are excellent illustrations of system-level optimization, which maximizes energy efficiency in both hot and cold climates by coordinating motor cooling, battery cooling, and HVAC through a single loop.

Furthermore, the companies such as Ather Energy and SUN Mobility are utilizing latent heat storage conductors in the electric vehicle removable battery packs, to ensure the thermal energy exchange at the best character for urban cities which are busily populated. Also, the strategies mentioned not only augment the performance but they also downsize the potential hazards of fires and thermal runaway of the batteries.

Comprehensive thermal management is also a key to the success of V2G (vehicle-to-grid) applications, as in the case of bi-directional fast charging heat cycling and the signals of cell life degradation. With the help of efficient TMS, battery resilience is increased, giving them extended use lifespan and thus guiding the car manufacturers to give better warranties and lifecycle economics.

Advanced Power Electronics: Precision at the Core of Efficiency

Power electronics—specifically, inverters and DC-DC converters—are currently undergoing immense innovation in 2025. The move from silicon-based to silicon carbide (SiC) and gallium nitride (GaN) semiconductors is making it possible for the electrical appliances to switch faster, as well as making them more thermally tolerant and energy-efficient.

OEMs such as Hyundai, Toyota, and Tata are already in the process of equipping their high-performance EVs with SiC inverters to speed up the time it takes to raise current and to lower electricity consumption. Certain electronic devices are designed to last longer as there is less heat production, and in turn, they save energy and are space-saving even with the high frequencies of operation thanks to the power model innovation that is the new wide band-gap semiconductors.

Startups like Chara Technologies and Log9 Materials are engaged in revolutionizing the electric vehicle industry with their powertrain-integrated controllers collaborating together with the inverter, motor controller, and the battery management system (BMS) for real-time information. This new system architecture is not only good for energy regeneration in non-motorized areas but also it provides torque vectoring for all-wheel-drive EVs, and it can additionally alter the performance profiles based on the traffic or terrain conditions dynamically.

There are also some rather unique breakthroughs in the automotive field, like the adaptive drive control unit that can nowadays adjust, if the situation demands so, the torque distribution across the motors constantly to maintain the vehicle’s stability in the event of a loss of traction—something of great significance in the world of autonomous or semi-autonomous driving.

Next-Gen Battery Packs: Modularity and Sustainability

Much more than the chemistry of batteries, battery pack architecture is changing. In 2025, the trend of modular and repairable battery packs is very strong in the market. Indian companies such as Log9 Materials and Matter Energy are encouraging modular battery solutions for electric two-wheelers and three-wheelers. With these packs, individual cells or modules can be exchanged without the whole battery having to be thrown away, which significantly decreases maintenance costs in the long run.

Even automakers are developing battery casings that function also as structural parts for the vehicle chassis. This new trend, named “cell-to-pack” (CTP) or “cell-to-chassis” (CTC) configurations, is associated with less excessive materials and more opportunities to create a better way of dealing with the heat and space effectiveness also.

Solid-state battery development is still ongoing, with Toyota, Samsung SDI, and QuantumScape projecting commercial readiness by 2027. As of 2025, the main goal is adding energy density, recyclability, and reducing cost-per-kWh with the use of lithium iron phosphate and NMC (nickel-manganese-cobalt) batteries that have been already proven to be functional. Lithium and cobalt recoverers at Attero and Lohum in India are now at the phase of setting up larger-scale facilities, thus, they had been serving as the guarantee of the absolute circularity of these raw materials to the domestic market.

Conclusion: EV Components Are the New Competitive Edge

In 2025, the competitive landscape has moved beyond electrification to component- level innovation in electric vehicles. OEM, Tier-1 and research and development facilities are ramping up more intelligent, safer and more efficient components that are the foundation of the upcoming wave of performance and scale of EVs.

The development of rare-earth-free motors, battery systems, thermal systems, lightweight structures, and high-voltage power electronics is fundamentally changing the way EVs are being designed, manufactured, and integrated into the consumer experience. Now, these technologies are no longer mere add-ons; they are key to brand differentiation, supply chain resilience, and sustainability standards.

What India needs to do is build that depth in the country in advanced components, rather than focus on just the final assembly of EVs, for India to act as the global hub for EV’s. area-by-area R&D clusters are likely to be the battleground with nimble component suppliers the emerging giants on the global scene as these players are integrated into trans-local downstream value chains.

Appreciating these nuanced component-level advances will enable businesses to invest wisely, pave the way for better OEM-supplier collaborations, and, in a word, speed up the transition to cleaner and smarter mobility.