The transition to electric vehicles (EVs) has accelerated rapidly as the world focuses on reducing carbon emissions and adopting sustainable transportation solutions. Central to the success of EVs is their battery technology, which directly affects vehicle range, performance, and efficiency. Among the latest advancements, lightweight traction battery packs have emerged as a game-changer, offering improved energy density and reduced weight. This article explores the materials and technological advancements driving the development of lightweight battery packs and their implications for EVs and EV charging infrastructure.

The Need for Lightweight Battery Packs in EVs

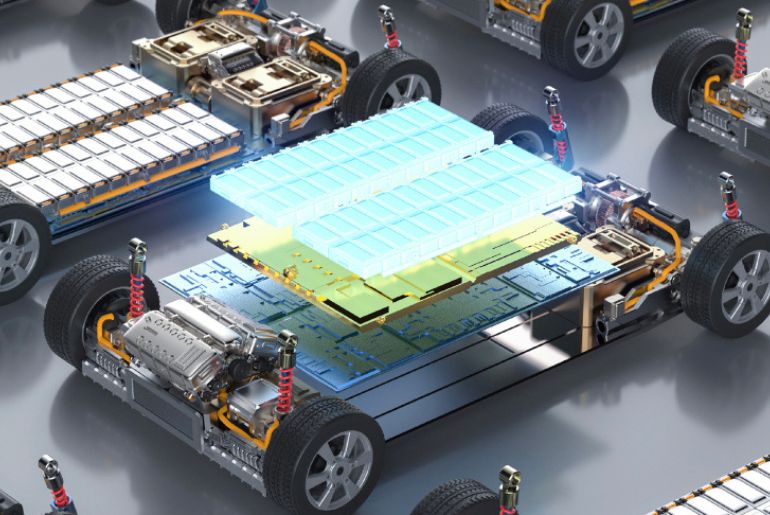

Electric vehicles rely on traction battery packs to power their motors. These battery packs are often the heaviest component in an EV, contributing significantly to the vehicle’s total weight. A heavier battery pack reduces overall energy efficiency, limits range, and increases wear on tires and suspension systems.

Reducing the weight of battery packs offers several benefits:

- Enhanced Range: A lighter EV requires less energy to move, enabling it to travel farther on a single charge.

- Improved Performance: Lightweight battery packs enhance acceleration, handling, and braking.

- Lower Charging Demand: Reduced weight means less energy consumption, which translates to shorter EV charging times.

- Cost Efficiency: Lightweight materials may reduce production and operational costs in the long term.

Materials Revolutionizing Battery Pack Design

The push for lightweight traction battery packs has led to a significant focus on advanced materials. Key materials being explored include:

- Aluminum and Magnesium Alloys

- These alloys are commonly used for battery enclosures and structural components due to their lightweight and corrosion-resistant properties. Magnesium, in particular, is 33% lighter than aluminum and offers comparable strength.

- Carbon Fiber Composites

- Carbon fiber is incredibly strong and lightweight, making it ideal for reinforcing battery cases and modules. Though expensive, ongoing advancements aim to reduce costs and improve scalability for EV manufacturers.

- High-Performance Polymers

- Polymers such as thermoplastics are used for insulation and structural elements. These materials are lightweight, flexible, and capable of withstanding high temperatures, making them ideal for advanced EV battery designs.

- Silicon Anodes

- Traditional graphite anodes are being replaced with silicon-based alternatives. Silicon anodes can store up to 10 times more lithium ions, leading to higher energy density. This allows for smaller, lighter battery packs without compromising capacity.

- Solid-State Electrolytes

- Solid-state batteries replace liquid electrolytes with solid materials, reducing the need for heavy casings. These batteries are not only lighter but also safer and capable of faster EV charging.

Technological Advancements in Lightweight Battery Packs

In addition to materials innovation, technological advancements are redefining how EV battery packs are designed, manufactured, and utilized:

- Battery Module Integration

- Traditional battery packs are composed of individual modules containing multiple cells. Modern designs aim to eliminate modules, directly integrating cells into the pack. This “cell-to-pack” technology reduces the need for additional structural components, cutting weight by up to 20%.

- 3D Printing

- Additive manufacturing techniques like 3D printing allow for the creation of intricate, lightweight battery components. By optimizing designs for strength and weight, 3D printing helps reduce excess material use.

- Advanced Cooling Systems

- Lightweight, efficient thermal management systems are critical for maintaining battery performance. Liquid-cooled designs with lightweight materials, such as aluminum channels, reduce the overall weight of the battery pack.

- Artificial Intelligence and Design Optimization

- AI and machine learning tools are being used to optimize battery design, minimizing material usage while maximizing performance and safety. These tools also predict stress points, reducing the need for over-engineering and excess weight.

Impact on Electric Vehicles

Lightweight traction battery packs are pivotal for the evolution of electric vehicles. By improving energy efficiency and extending range, these innovations address two major concerns for EV adoption: range anxiety and energy consumption.

Additionally, lighter EVs reduce wear and tear on roads and tires, lowering maintenance costs. This advantage is particularly critical for fleet operators using EVs for logistics and ride-sharing services. With lighter battery packs, commercial EVs can achieve greater operational efficiency, reducing total cost of ownership.

Implications for EV Charging Infrastructure

The advancements in lightweight battery packs also directly influence EV charging systems. As battery packs become lighter and more efficient:

- Reduced Charging Times: Lightweight batteries with higher energy density require less energy per mile, enabling faster EV charging sessions.

- Lower Grid Impact: With lower charging demands, lightweight EVs help reduce stress on power grids, particularly during peak hours.

- Optimized Charging Station Design: Lightweight batteries enable ultra-fast charging technologies without the risk of overheating, simplifying charging station thermal management systems.

- Integration with Renewable Energy: Efficient batteries improve compatibility with renewable energy sources, allowing charging stations powered by solar or wind energy to operate more effectively.

Challenges and Future Prospects

While lightweight traction battery packs offer numerous advantages, challenges remain:

- Cost: Advanced materials like carbon fiber and silicon are still expensive, impacting EV affordability.

- Manufacturing Scalability: High-performance materials and innovative designs require advanced manufacturing processes, which need to scale to meet global EV demand.

- Battery Recycling: Lightweight materials and complex designs can complicate the recycling process, raising concerns about end-of-life management for EV batteries.

However, research and development continue to address these challenges. Governments and private enterprises are investing heavily in battery technology, ensuring that lightweight traction battery packs become more affordable and accessible.

Conclusion

The development of lightweight traction battery packs marks a significant step forward in advancing electric vehicles and EV charging infrastructure. By leveraging innovative materials and cutting-edge technologies, these battery packs enhance range, performance, and efficiency while reducing energy consumption. As the global shift to EVs accelerates, lightweight battery solutions will play a crucial role in making electric vehicles a practical and sustainable choice for all.

With ongoing advancements, the collaboration between the automotive and energy sectors promises a future where EVs and EV charging systems are more efficient, environmentally friendly, and seamlessly integrated into our daily lives. Lightweight battery packs are not just an innovation—they are a cornerstone of the EV revolution.