Later this year, GM plans to start switching its Tennessee battery plant’s production lines to low-cost LFP EV batteries. As it gets ready for a new age, GM’s joint venture Ultium Cells announced more improvements to the plant on Monday.

In the US, GM will produce inexpensive LFP EV batteries.

GM is expanding its lead in 2025 after surpassing Ford and Hyundai to become the second-best EV seller in America last year.

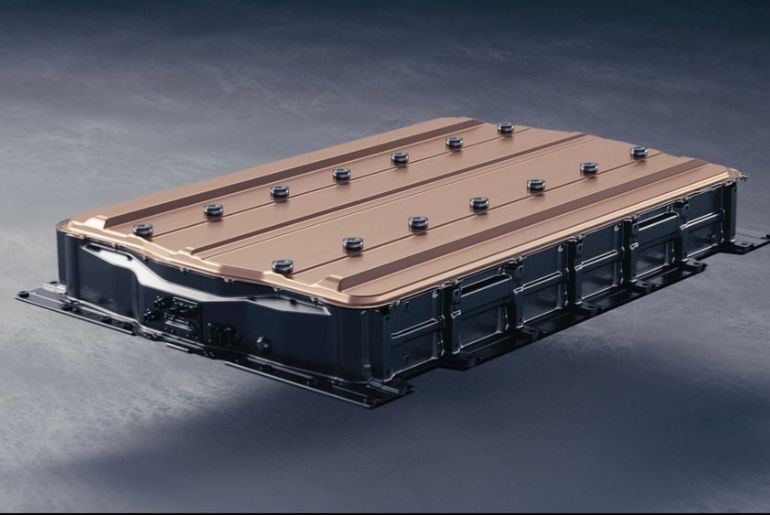

As it gets ready to launch less expensive lithium-iron-phosphate (LFP) battery cells, GM’s joint venture with LG Energy Solution, Ultium Cells, revealed plans on Monday to improve its Tennessee battery factory.

The improvements expand upon the $2.3 billion commitment made in April 2021 to transform the building into a major hub for EVs and batteries. Although GM was still dedicated to an all-electric future at the time, the firm initially claimed that the Tennessee plant was “at the heart of GM’s EV strategy“.

Later this year, GM will start modifying manufacturing lines at the plant to make room for the less expensive LFP batteries. The business anticipates beginning commercial production by the end of 2027.

With LFP batteries, GM stated that it is “aiming to increase consumer EV choice while achieving significant battery pack cost savings compared to today’s high-nickel battery pack.”

Currently, the facility in Spring Hill, Tennessee, has over 1,300 workers. According to GM, the plant will “guide the next phase of” its battery strategy because it can generate several chemistries.

Finding a location for batteries rich in lithium manganese is the next stage, according to GM, after selecting Spring Hill for its LFP batteries. GM recently declared its intention to become the first business to manufacture LMR prismatic battery cells on a large scale.

In the meantime, GM’s Warren, Ohio, facility will keep making NCM batteries, which it claims have enabled it to achieve a range of more than 300 miles.