The shift from internal combustion engine vehicles to electric vehicles (EVs) represents a significant step towards sustainable and environmentally friendly transportation. A critical component of this transition is the battery, which serves as the heart of the EV. Ensuring the optimal performance and longevity of EV batteries necessitates advanced Battery Thermal Management Systems (BTMS). These systems play a pivotal role in maintaining battery health, efficiency, and safety by regulating the temperature within the optimal range. This article delves into the importance, working principles, and advancements in BTMS for EV powertrains.

Importance of Battery Thermal Management Systems

-

Performance Optimization:

EV batteries operate most efficiently within a specific temperature range. Extreme temperatures, whether high or low, can significantly affect the battery’s performance. High temperatures can accelerate the degradation of battery materials, reducing the overall lifespan and efficiency. Conversely, low temperatures can reduce the battery’s ability to deliver power, affecting the vehicle’s range and performance.

-

Safety:

Battery thermal runaway, a condition where the battery’s temperature uncontrollably rises, can lead to fires or explosions. Effective BTMS are crucial in preventing such scenarios by ensuring that the battery temperature remains within safe limits.

-

Longevity:

Prolonged exposure to suboptimal temperatures can lead to faster degradation of battery cells. By maintaining an optimal thermal environment, BTMS extend the life of the battery, providing better value for consumers and reducing the need for frequent replacements.

Working Principles of Battery Thermal Management Systems

BTMS use various methods to regulate the temperature of EV batteries. These methods can be broadly categorized into passive and active systems.

-

Passive Thermal Management:

Passive systems rely on the natural properties of materials and design to regulate temperature. This includes the use of thermal insulation, phase change materials (PCMs), and heat sinks. While passive systems are simpler and consume less energy, they are typically less effective in managing extreme temperatures compared to active systems.

-

Active Thermal Management:

Active systems use external mechanisms to control the battery temperature. These systems are more complex and energy-intensive, but they offer superior temperature regulation. Active thermal management can be further divided into air cooling, liquid cooling, and refrigerant cooling.

- Air cooling Uses fans or blowers to circulate air around the battery pack. While cost-effective, air cooling is less efficient in removing heat compared to liquid cooling and may struggle in high-performance applications.

- Liquid Cooling: Circulates a liquid coolant through a series of channels or plates in contact with the battery cells. Liquid cooling offers better heat transfer capabilities and is more effective in maintaining uniform temperature across the battery pack.

- Refrigerant Cooling: Uses a refrigerant in a vapor-compression cycle to provide cooling. This method is highly effective in removing heat and is commonly used in high-performance EVs and hybrid vehicles.

Advancements in Battery Thermal Management Systems

The rapid evolution of EV technology has driven significant advancements in BTMS. These innovations aim to improve efficiency, reliability, and integration within the vehicle’s overall thermal management strategy.

-

Integrated Thermal Management Systems:

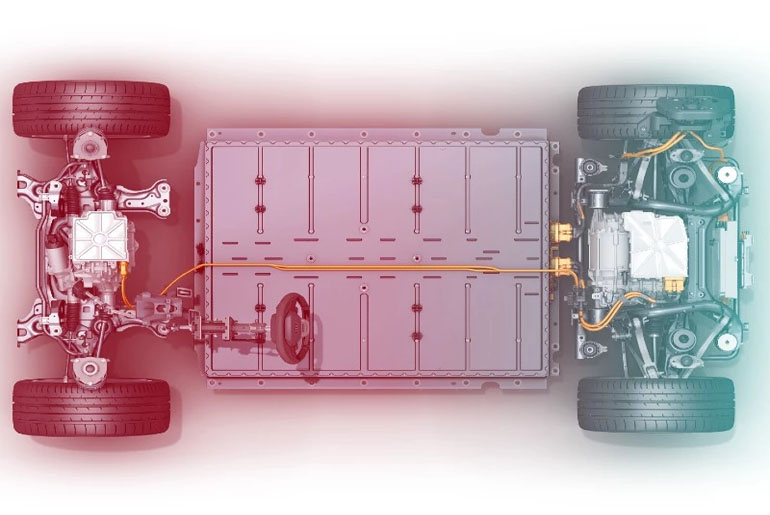

Modern EVs often use integrated thermal management systems that manage not only the battery but also the power electronics and cabin climate control. By using a single system to manage multiple thermal loads, manufacturers can achieve better overall efficiency and reduce the vehicle’s weight and complexity.

-

Smart Thermal Management:

The integration of sensors, advanced control algorithms, and machine learning allows for more precise and adaptive thermal management. Smart BTMS can predict thermal behavior based on driving patterns and environmental conditions, optimizing cooling or heating efforts accordingly.

-

Advanced Materials:

The development of new materials, such as high-conductivity thermal interface materials (TIMs) and advanced phase change materials (PCMs), enhances the efficiency of both passive and active thermal management systems. These materials provide better heat transfer properties and can help maintain a uniform temperature across the battery pack.

-

Battery Pack Design:

Innovations in battery pack design, such as modular and flexible configurations, facilitate more effective thermal management. Enhanced designs ensure better airflow, improved contact with cooling plates, and more efficient heat dissipation.

Future Prospects

The future of BTMS in EV powertrains is promising, with ongoing research and development focused on further enhancing efficiency, reducing energy consumption, and improving integration with other vehicle systems. Emerging technologies, such as solid-state batteries, which generate less heat, and advanced thermal management materials, will play a crucial role in the next generation of EVs.

Conclusion

Battery Thermal Management Systems are essential for the optimal performance, safety, and longevity of EV powertrains. As EV technology continues to evolve, advancements in BTMS will be critical in addressing the challenges associated with battery temperature regulation. By ensuring that batteries operate within their optimal temperature range, BTMS not only enhance the efficiency and reliability of electric vehicles but also contribute to the broader goal of sustainable and eco-friendly transportation.